So, the question on everyone’s mind: does CBG have THC? Let’s dive right in, shall we? It’s like embarking on a treasure hunt, but instead of gold doubloons, we’re after the secrets hidden within the fascinating world of cannabinoids. CBG, or cannabigerol, often gets overshadowed by its more famous cousins, but trust me, it’s got its own story to tell.

THC, or tetrahydrocannabinol, is the star of the show for its psychoactive properties. This is a journey to uncover the intricate relationship between these two compounds, where science meets everyday life.

Understanding the molecular structures of CBG and THC is like comparing two secret codes – they share some similarities but have unique keys that unlock different experiences within our bodies. Think of them as siblings; they share a family resemblance but each has a distinct personality. Extraction methods can be the plot twists in our story, affecting the final concentration of THC.

We will explore how different techniques, like careful farming and precision extraction, can affect the amount of THC in CBG products, making sure that what you’re getting is exactly what you expect.

Understanding the Fundamental Chemical Structures of CBG and THC is Crucial for Accurate Comparisons

Navigating the world of cannabinoids requires a solid understanding of their fundamental building blocks. To truly appreciate the differences and potential of CBG (cannabigerol) and THC (tetrahydrocannabinol), we must first delve into their molecular architectures. This knowledge forms the bedrock for informed decisions regarding usage, effects, and therapeutic applications.

Molecular Composition of CBG and THC

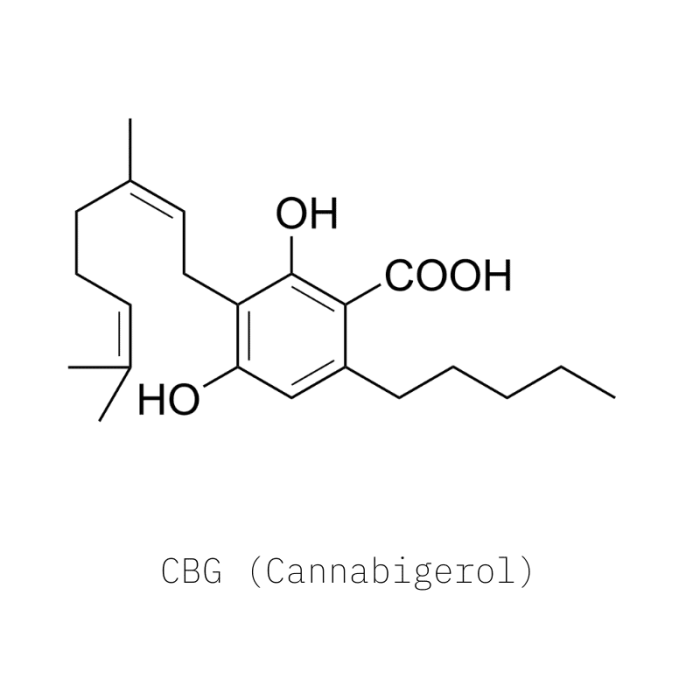

The chemical structures of CBG and THC, though related, hold the key to their distinct properties. Both compounds are cannabinoids, meaning they share a core structure based on the terpenophenolic skeleton. However, subtle variations in this structure lead to significant differences in their interactions with the human body.CBG, often referred to as the “mother of all cannabinoids,” exists in its acidic form as CBGA (cannabigerolic acid) in the cannabis plant.

During the plant’s growth, enzymes convert CBGA into other cannabinoids, including THCA (tetrahydrocannabinolic acid), the precursor to THC. CBG itself is formed through the decarboxylation (removal of a carbon atom and two oxygen atoms) of CBGA. Its structure features a carboxyl group (-COOH) attached to the main ring structure, making it a slightly different shape compared to THC.THC, on the other hand, is the primary psychoactive compound in cannabis.

Its structure differs from CBG primarily in the arrangement of atoms within the molecule. The most notable difference lies in the position of a double bond in the carbon ring and the presence of a cyclic ring structure. This small change allows THC to bind strongly to the CB1 receptors in the brain, triggering the psychoactive effects commonly associated with cannabis.

THC’s molecular formula is C21H 30O 2, while CBG’s is C21H 32O 2. The difference in one hydrogen atom and the configuration of atoms is what separates the two. This difference, though minute, has a profound impact on how they interact with the body’s endocannabinoid system (ECS). The ECS is a complex network of receptors and neurotransmitters that play a crucial role in regulating various physiological functions, including pain, mood, and appetite.

Comparison Table: CBG vs. THC, Does cbg have thc

Understanding the distinctions between CBG and THC becomes clearer when presented side-by-side. The following table highlights the key differences:

| Characteristic | CBG (Cannabigerol) | THC (Tetrahydrocannabinol) |

|---|---|---|

| Molecular Formula | C21H32O2 | C21H30O2 |

| Psychoactive Effects | Generally considered non-psychoactive; may produce mild effects at very high doses. | Highly psychoactive; responsible for the “high” associated with cannabis. |

| Primary Therapeutic Applications |

|

|

Extraction Methods and THC Concentration in CBG Products

The method used to extract cannabinoids from the cannabis plant can significantly impact the final composition of the product, including the concentration of THC in CBG products. Several techniques are employed, each with its own advantages and disadvantages.* CO2 Extraction: This method utilizes carbon dioxide under high pressure and low temperatures to separate cannabinoids from the plant material.

It is generally considered a clean and efficient method, capable of producing extracts with varying cannabinoid profiles. The degree to which THC is present depends on the specific parameters of the extraction process and the starting plant material.* Solvent Extraction: Solvents like ethanol or butane are used to dissolve the cannabinoids. This method can be cost-effective, but it requires careful purification to remove residual solvents.

The potential for THC contamination exists if the source material contains THC or if the extraction process is not meticulously controlled.* Isolate Production: The goal of producing CBG isolate is to create a product with a very high concentration of CBG and minimal amounts of other cannabinoids, including THC. However, achieving 100% purity is extremely difficult, and trace amounts of THC may still be present.

This is a crucial consideration for individuals who are sensitive to THC or subject to drug testing.The presence of THC in CBG products, even in trace amounts, can influence the overall effects and potential benefits. It is therefore vital to understand the extraction method used and to review third-party lab reports to verify the cannabinoid profile and ensure that the product meets the user’s specific needs and legal requirements.

Exploring the Methods Used to Detect Trace Amounts of THC in CBG Products is Important

Understanding how laboratories meticulously identify and quantify THC in CBG products is crucial for consumer safety and regulatory compliance. The sensitivity and accuracy of these methods are paramount, ensuring that products are accurately labeled and meet legal thresholds. This exploration delves into the sophisticated techniques employed, highlighting their capabilities and limitations.

Laboratory Techniques for THC Detection

Detecting trace amounts of THC in CBG products requires highly sensitive and accurate analytical techniques. Several methods are commonly used, each with its strengths and weaknesses. These methods are designed to differentiate between the various cannabinoids present, including CBG and THC, allowing for precise quantification of each compound.Gas Chromatography-Mass Spectrometry (GC-MS) is a widely used technique. This method separates different compounds based on their boiling points, using a gas chromatograph, and then identifies them based on their mass-to-charge ratio using a mass spectrometer.* GC-MS offers exceptional sensitivity, often capable of detecting THC concentrations as low as 0.001% (1 part per million or ppm).

- The accuracy of GC-MS is high, with a typical margin of error of less than 5%.

- GC-MS is particularly useful for detecting a broad range of cannabinoids and other volatile organic compounds.

High-Performance Liquid Chromatography (HPLC) is another prevalent technique. Unlike GC-MS, HPLC separates compounds based on their interaction with a liquid mobile phase and a solid stationary phase.* HPLC is well-suited for analyzing thermally unstable compounds, as it operates at lower temperatures than GC-MS.

- The sensitivity of HPLC is slightly lower than GC-MS, typically detecting THC concentrations down to 0.01% (100 ppm).

- HPLC’s accuracy is generally comparable to GC-MS, with a similar margin of error.

Liquid Chromatography-Mass Spectrometry (LC-MS) combines the separation power of HPLC with the detection capabilities of mass spectrometry.* LC-MS offers high sensitivity and can detect very low levels of THC, similar to or even better than GC-MS.

- This technique is particularly useful for complex matrices, where multiple compounds are present.

- LC-MS provides a highly accurate quantification of THC, with similar error margins to GC-MS and HPLC.

These methods are often used in combination to provide a comprehensive analysis of CBG products. For example, a laboratory might use GC-MS for initial screening and HPLC or LC-MS for confirmation and more precise quantification. The choice of technique depends on factors such as the expected THC concentration, the complexity of the sample matrix, and the specific regulatory requirements.

Step-by-Step Laboratory Testing Procedures

The process of testing CBG products for THC contamination involves a series of carefully executed steps, ensuring accuracy and reliability. These steps are typically followed in a standardized laboratory setting.

1. Sample Preparation

The process begins with the careful preparation of the CBG product sample. This often involves weighing a specific amount of the product and dissolving it in a suitable solvent, such as methanol or acetonitrile. The solvent helps to extract the cannabinoids from the sample.

2. Extraction

Depending on the product type (e.g., oil, flower, extract), additional extraction steps might be necessary. This may involve using techniques like sonication or solid-phase extraction to isolate the cannabinoids from the sample matrix.

3. Filtration

The prepared sample is then filtered to remove any particulate matter that could interfere with the analysis. This ensures that only the dissolved compounds enter the analytical instrument.

4. Instrument Calibration

Before analyzing the samples, the analytical instrument (GC-MS, HPLC, or LC-MS) must be calibrated using known standards of THC and other cannabinoids. This ensures the instrument can accurately quantify the THC present.

5. Sample Injection

The prepared sample is injected into the analytical instrument. The instrument then separates the cannabinoids and measures their concentrations.

6. Data Analysis

The instrument generates data that is then analyzed using specialized software. This software identifies and quantifies the THC present in the sample, comparing the results to the calibration standards.

7. Result Reporting

Finally, the laboratory reports the results, including the THC concentration and any other relevant information, such as the uncertainty of the measurement. The results are typically reported as a percentage of the total product weight.

Visual Representation of the THC Detection Process

Imagine a visual representation of the THC detection process as a flowing river, starting from the source (the CBG product) and culminating in a clear, quantified result.The river begins as a swirling mass, representing the

- CBG Product Sample*. This mass enters a

- Sample Preparation Station*, where it is meticulously weighed and dissolved in a clear solvent, transforming into a homogenous solution. The solution then flows through a

- Filtration Chamber*, where any solid particles are removed, leaving a pristine liquid ready for analysis.

Next, the solution moves into theAnalytical Instrument*, depicted as a complex machine with intricate pipes and detectors. Inside, the solution undergoes separation and analysis, represented by a colorful diagram showing the separation of different compounds. The data generated is displayed on a screen, with graphs and charts showing the concentration of THC.Finally, the river culminates in a clear, labeled container displaying theTHC Concentration*, a precise numerical value, along with the

Uncertainty of Measurement*, showing the range of possible values. The river represents the entire process, illustrating the journey from a complex sample to a clear, quantifiable result. The illustration emphasizes the key steps

sample preparation, extraction, filtration, instrument calibration, sample injection, data analysis, and result reporting, all working in harmony to deliver accurate and reliable results.

The Legal Landscape and Regulations Surrounding THC Content in CBG Products Needs Clarity: Does Cbg Have Thc

Navigating the legal terrain surrounding CBG products is akin to charting a course through a dense fog. The regulations governing THC content are a patchwork, varying wildly across jurisdictions and often subject to interpretation. This lack of uniformity can lead to confusion for both consumers and producers, creating a landscape ripe with potential pitfalls. Understanding the legal definitions and their implications is crucial for anyone involved in the CBG market.

Legal Definitions of Hemp and Cannabis and Their Impact

The cornerstone of legal compliance lies in the definitions of “hemp” and “cannabis.” These definitions, while seemingly straightforward, are the key determinants of whether a CBG product is legally permissible.The legal definition of “hemp” frequently hinges on the concentration of delta-9 tetrahydrocannabinol (THC). The 2018 Farm Bill in the United States, for instance, defines hemp as cannabis plants containing no more than 0.3% THC on a dry weight basis.

Anything exceeding this threshold is generally classified as marijuana, a substance that remains federally illegal, although its legal status varies by state. This is where things get tricky.

The 0.3% THC threshold, while a widely adopted standard, is not universally accepted.

Different regions and countries have their own variations, and some may have stricter or more lenient limits. The European Union, for example, has a slightly different approach to defining hemp. The impact of these varying definitions is multifaceted:* Production: Farmers must meticulously monitor and test their crops to ensure compliance with the legal THC limits. Non-compliance can lead to the destruction of entire harvests and severe financial penalties.

Processing

Extractors and manufacturers must employ precise methods to isolate CBG and remove or minimize THC content. The choice of extraction method and the quality of the starting material are critical factors.

Distribution and Sales

Retailers and distributors must be aware of the legal limits in their respective jurisdictions and ensure that their products are accurately labeled and tested. Cross-border trade is further complicated by differing regulations.

Consumer Safety

The legal definition impacts the consumer’s exposure to THC. Consumers need to be aware of the THC content of the products they are purchasing.

Current Regulations and Guidelines Regarding THC Content in CBG Products

A closer look at the current regulations reveals a diverse range of approaches. The following examples highlight the variability in THC limits and labeling requirements:* United States:

As mentioned, the 2018 Farm Bill established a federal definition of hemp with a 0.3% THC limit.

States have the authority to create their own regulations, and some have adopted stricter limits or additional requirements, such as mandatory testing and labeling.

Labeling typically includes the total THC content, along with the CBG content and other cannabinoids. –

Canada

Canada’s Cannabis Act regulates cannabis, including hemp.

Health Canada sets the standards for THC limits in hemp products.

Labeling must include the THC and CBD content, as well as warnings and other required information.

European Union

The EU allows for the cultivation of hemp varieties with less than 0.3% THC.

Individual member states can implement their own regulations, leading to variations in permissible THC levels.

Labeling requirements are in place, but these may vary by country.

United Kingdom

The UK follows EU guidelines.

The Home Office regulates the cultivation and processing of hemp.

Products must comply with a THC limit and have appropriate labeling.

These examples highlight the need for producers and consumers to stay informed about the specific regulations in their respective locations.

Potential for Changes in Regulations

The legal landscape surrounding CBG and THC is not static; it is subject to change. Several factors could influence future regulations:* Evolving Scientific Understanding: As research into cannabinoids continues, our understanding of their effects and potential benefits will improve. This could lead to adjustments in THC limits or the development of new regulations based on scientific evidence. For example, future research could reveal that certain levels of THC, previously considered problematic, may not pose a significant risk, or that other cannabinoids interact in ways that mitigate the effects of THC.

Public Policy Shifts

Changes in public opinion and political priorities can also drive regulatory changes. As the popularity of CBG products grows, policymakers may be pressured to create clearer and more consistent regulations. The legalization of recreational marijuana in several states in the US is an example of a policy shift. This could also lead to changes in the definition of “hemp” or “cannabis” or the permissible levels of THC in hemp products.

Consumer Demand

Consumer preferences and demand can influence regulatory changes. If consumers increasingly seek out products with specific cannabinoid profiles, regulators may respond by creating standards and guidelines to meet these demands. The growing demand for CBG-dominant products could put pressure on regulators to establish clearer guidelines for testing and labeling. Possible future scenarios include:

Increased THC Limits

Some jurisdictions might increase the allowable THC limit for hemp products based on scientific evidence.

Standardized Testing Methods

The development and implementation of standardized testing methods could improve accuracy and consistency across different laboratories.

Harmonization of Regulations

Efforts to harmonize regulations across different countries or regions could simplify the legal landscape and facilitate international trade. The key takeaway is that the regulations governing THC content in CBG products are likely to evolve. Staying informed about these changes is crucial for anyone involved in the CBG market.

The Potential for Cross-Contamination During CBG Production Should be Considered

The journey from seed to shelf for CBG products is a delicate one, fraught with potential pitfalls that could lead to unwanted THC contamination. While the goal is to produce a pure CBG isolate or product, the presence of even trace amounts of THC can have significant legal and health implications. Therefore, understanding the stages where cross-contamination is most likely, and implementing rigorous preventative measures, is absolutely critical for any CBG producer.

This requires a comprehensive approach, from the initial selection of cannabis genetics to the final packaging of the finished product.

Cross-Contamination Stages in CBG Production

The potential for THC contamination lurks at every stage of CBG production. From the fields where the plants are cultivated to the labs where the extract is refined, vigilance is key. The most vulnerable points include cultivation, harvesting, extraction, and manufacturing. Each of these phases presents unique challenges and requires specific preventative measures to minimize the risk of contamination. These measures are not just about compliance; they are about consumer safety and maintaining the integrity of the CBG product.During the cultivation phase, the most significant risk comes from growing CBG-dominant strains alongside THC-dominant strains or in fields that have previously housed THC-producing plants.

Pollen drift from THC-containing plants can fertilize CBG plants, leading to the development of THC in the buds. In the harvesting stage, using the same equipment (trimmers, drying racks, etc.) for both THC and CBG crops without thorough cleaning poses a direct contamination risk. Similarly, during the extraction process, if equipment is not properly cleaned between batches of different cannabis varieties, or if solvents are used that have previously been used for THC extraction, THC can be carried over.

Finally, in the manufacturing phase, where CBG extracts are formulated into various products (oils, edibles, topicals), cross-contamination can occur if the same equipment or work areas are used for both CBG and THC-containing products without proper separation and cleaning protocols.Here are some common production practices that can lead to THC contamination, along with recommended solutions:

-

Using the same cultivation space for both CBG and THC-containing plants:

Solution: Dedicate separate, isolated grow rooms or outdoor fields for CBG cultivation. Ensure physical barriers and strict airflow management to prevent pollen drift. Implement a rigorous cleaning protocol for all equipment and surfaces between uses.

-

Harvesting with equipment used for THC-containing plants:

Solution: Designate separate harvesting equipment for CBG crops. If shared equipment is unavoidable, implement a meticulous cleaning and sanitization procedure between uses, including dismantling and thoroughly cleaning all parts. This should be documented and regularly audited.

-

Extracting CBG using equipment that has processed THC-containing material:

Solution: Establish dedicated extraction equipment for CBG. If this is not feasible, implement a comprehensive cleaning protocol that includes solvent flushes, disassembly, and visual inspection to ensure no residue remains. Use validated cleaning methods and document all cleaning activities.

-

Formulating CBG products in a facility that also processes THC products:

Solution: Establish dedicated manufacturing areas for CBG products, physically separated from THC-containing product lines. Implement strict cleaning and sanitation protocols, including the use of dedicated utensils, containers, and processing equipment. Conduct regular testing of surfaces and equipment to ensure cleanliness.

-

Using contaminated solvents:

Solution: Always use high-purity, food-grade solvents. Implement a system for tracking solvent usage and storage. Ensure that solvents are not used for both THC and CBG extraction without thorough cleaning and testing.

-

Inadequate testing of raw materials and finished products:

Solution: Conduct comprehensive testing of all raw materials (e.g., biomass, solvents, additives) and finished products by an accredited third-party laboratory. Establish a robust quality control program that includes regular testing for THC, other cannabinoids, and contaminants.

A hypothetical scenario: A CBG producer, focused on achieving the highest purity, cultivated its CBG-dominant plants in a greenhouse adjacent to a research facility growing various cannabis strains, including some with higher THC content. Despite the physical separation, pollen from the research facility’s plants drifted into the CBG greenhouse, leading to cross-pollination. During routine testing of the harvested biomass, a third-party laboratory detected a THC concentration exceeding the legal limit for the intended market. The producer immediately quarantined the affected batch. The cause was identified through genetic testing of the contaminated plants and a review of the cultivation practices, revealing a lapse in air filtration and insufficient monitoring of pollen drift. The producer then implemented stricter environmental controls, including HEPA filters and regular pollen monitoring. The extraction process was reviewed, and a more thorough cleaning protocol for all equipment was established. All finished products were retested, and the contaminated batch was destroyed. The producer also retrained all staff on contamination prevention protocols and revised its standard operating procedures (SOPs) to include these new measures. This situation highlights the importance of meticulous planning and consistent execution in CBG production.

Consumer Awareness and Product Labeling Play a Vital Role in Transparency Regarding THC Content

Navigating the world of CBG products can feel like trying to decipher a secret code. Clear and accurate product labeling acts as your Rosetta Stone, unlocking the information you need to make informed choices. Without it, consumers are left in the dark, potentially exposed to unwanted THC and unable to tailor their CBG experience to their specific needs. Transparency builds trust, and trust is the cornerstone of a thriving and safe industry.

It’s about empowering consumers with the knowledge they deserve.Accurate product labeling is paramount for several reasons. It ensures consumers are aware of the presence and concentration of THC, enabling them to make informed decisions based on their personal tolerance levels and legal restrictions. This awareness is critical for individuals who are sensitive to THC or who are subject to drug testing.

Furthermore, transparent labeling promotes safety by preventing accidental overconsumption and mitigating potential adverse effects. It also fosters trust in brands, as consumers are more likely to support companies that prioritize honesty and provide readily accessible information about their products. In an industry with varying regulations, clear labeling is not just a best practice; it’s a responsibility.

Interpreting Product Labels for THC Content

Understanding how to read a CBG product label is like learning a new language – once you grasp the basics, you’ll be fluent in making informed choices. Let’s break down the key elements to look for:

- Total CBG Content: This tells you the total amount of CBG in the product, usually expressed in milligrams (mg). This helps you understand the potency of the product.

- THC Content: This is the crucial piece of information. Look for the total THC content, often also in mg, and sometimes expressed as a percentage. Pay close attention to this, especially if you’re concerned about THC exposure.

- Serving Size: This specifies the recommended amount to consume. The THC content listed is usually per serving, so understanding the serving size is vital for calculating your intake.

- Third-Party Lab Testing: Reputable brands provide a Certificate of Analysis (COA) from an independent lab. This document verifies the cannabinoid content and confirms that the product meets the label claims. Look for a QR code or a link to the COA.

- Batch Number/Lot Number: This number links the product to a specific batch tested by the lab. This is useful if you need to trace the product or if there are any issues with the product.

- Ingredients List: This lists all the ingredients in the product. This is important if you have any allergies or sensitivities.

Comparing Product Labeling: Examples

Here’s a comparison of how different product labels might present information. Imagine these as real-world examples to guide your understanding:

| Label Example | Information Provided | Clarity of Presentation |

|---|---|---|

| Label A: CBG Oil, 1000mg CBG, THC: <0.3%, Serving Size: 1mL, Ingredients: … | Provides total CBG, THC content (as a percentage), serving size, and ingredients. | Clear and concise, uses common terminology. The “<0.3%" is a standard and easily understood way to communicate the THC level. |

| Label B: CBG Tincture, 800mg CBG, THC: 2mg per serving, Serving Size: 0.5mL, Ingredients: … Includes COA link | Offers total CBG, THC content per serving, serving size, and ingredients, plus a link to a Certificate of Analysis. | Slightly more detailed with THC per serving, which is helpful. The COA link enhances transparency. |

| Label C: CBG Gummies, 50mg CBG per gummy, THC: 5mg per gummy, Serving Size: 1 gummy, Ingredients: … Contains QR code for COA | Specifies CBG and THC content per gummy, serving size, and ingredients. Includes a QR code for easy access to the COA. | Excellent clarity, as the information is directly relevant to the serving size, making it simple to understand the dose of each gummy. The QR code adds convenience. |

| Label D: CBG Capsules, 25mg CBG, Contains trace amounts of THC, Serving Size: 1 capsule, Ingredients: … | Provides CBG content, mentions “trace amounts” of THC, serving size, and ingredients. | Less specific regarding THC. While mentioning “trace amounts” is better than nothing, it lacks a quantifiable amount, which is less informative. |